LOGISTICS

Tele Radio offers wireless solutions for many logistic applications

A remote control does not only significantly increase the efficiency of work, but it also creates a safe work environment for humans and reduces the risk of damaging matters such as storage racks or conveyor belts.

We have solutions for storage systems, conveyor belts, forklifts and more. With our remote controls all sorts of logistic applications can easily be wirelessly controlled for a better view for the operator and from a safe distance.

We offer remote controls with a certified safety stop that meets the safety standards PLe/CAT3, SIL3 is essential in terms of safety. If there is an error message or if the transmitter is out of range of the receiver, the safety stop will be activated automatically. The tilt and fall sensor automatically disables the system in the event of an unexpected, potentially dangerous movement. This prevents the unwanted pressing of buttons and activation of functions and guarantees the necessary safety. A must for many logistic applications.

APPLICATIONS

To give an idea of the possibilities, we have some examples of applications and their typical products below:

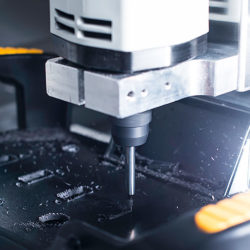

CONVEYOR BELTS

Transportation belts to move products or construction materials, either in a warehouse, a mine or attached to a vehicle. These belts can be controlled with a remote control to maintain a safe distance and a better view for the operator. Wireless remote controls also reduce the risk of tripping over cables.

PALLET SHUTTLE SYSTEMS

In warehouses, a pallet shuttle system significantly increases storage capacity and work efficiency. This is because it is an electrically powered storage system that makes loading and unloading pallets faster and safer and ensures a higher degree of rack filling. Pallet shuttle systems are often controlled wirelessly.

FORKLIFTS

A forklift truck, also known as a forklift or lift truck, is a means of transport driven by an electric motor or a combustion engine, mainly for the transport of goods that are on a pallet, for example in a warehouse or on a company site. For use in the warehouse, forklift trucks with a remote control are best suited.

Your preferences for security and functionality

To choose the transmitter best suited to your needs, it is best to consult your Tele Radio team. We provide different transmitters with specific characteristics. The following three elements are decisive for the choice:

Safety Level

Our transmitters are safe and many models have independent safety certification. This means that the operation of the stop button has been tested and verified by an external and independent body. We recommend choosing a system with independent safety certification if you want to minimize the risk of injury when using machinery. No security risk? Then you can choose a transmitter without certification.

Push Buttons or Joysticks

The use of buttons makes the transmitter more manageable, but certainly not less precise. A transmitter with proportional buttons, for example, has the accuracy of a joystick transmitter. Pressing the button further increases the degree of activation. A joystick transmitter is larger, but has more customization options, such as special buttons and switches.

Feedback

Some transmitters can receive information from a controlled receiver. Depending on the system, information can be made visible via LEDs on the transmitter or via a display. For example, when controlling a crane, you can use the display to view information such as the weight to be lifted or alarms. This feature is less important for less complex applications, such as truck winches.

Contact us for more information

Tele Radio supports the world wide preservation of the Tiger with WWF.

Tele Radio supports the world wide preservation of the Tiger with WWF.